In the high-stakes world of maritime operations, few tasks are as critical—and as hazardous—as welding. From structural repairs and pipeline maintenance to fabrication projects at sea, welding plays a pivotal role in keeping vessels operational.

However, this essential activity also introduces serious risks, particularly when equipment is not maintained to the highest standards.

Welding-related incidents are a leading cause of fires, injuries, and vessel damage, often stemming from lapses in inspection protocols or neglected maintenance.

These risks are compounded in the unique environment of a ship, where space is limited, flammable materials abound, and response time in emergencies is severely restricted.

Now, with the adoption of the enhanced RightShip RISQ 2.0 and 3.1 standards, and the broader rollout of SIRE 2.0, the stakes are even higher.

Proper maintenance of welding equipment is no longer a recommendation—it’s a requirement with direct consequences for safety, compliance, and commercial viability.

The Inherent Risks of Welding at Sea

Welding on a moving vessel is fundamentally different from welding in a land-based facility.

The marine environment introduces vibration, moisture, temperature fluctuations, and spatial constraints—all of which amplify risk.

Poorly maintained welding equipment can result in:

Fires and explosions: Confined areas near fuel systems or engine rooms make any spark a potential disaster. Faulty shielding or degraded components elevate this risk.

Toxic fumes: Welding releases hazardous gases and metal particulates. In enclosed or poorly ventilated areas, without proper fume extraction or sealed equipment, crew members may suffer serious health consequences.

Electric shocks: Exposed wiring, corroded terminals, and frayed cables create life - threatening shock hazards, particularly in wet or humid conditions.

Physical injuries: Unreliable equipment increases the chances of burns, eye damage from UV radiation, and injuries from molten metal or flying sparks.

A small oversight, such as a cracked hose or malfunctioning regulator, can spiral into a life-threatening situation.

When a fire breaks out at sea, options are limited. The closest help may be hours—or days—away.

Maintenance: The First Line of Defense

Ensuring the integrity of welding equipment through regular servicing is a proactive step that pays dividends in safety and reliability. Maintenance goes beyond visual checks. It involves thorough inspections, testing, and replacement of worn components—all essential in the corrosive marine environment.

Key maintenance practices include:

- Verifying the integrity of cables, earth clamps, and connectors to prevent overheating or short-circuiting.

- Checking flashback arrestors and regulators to ensure reverse gas flow is impossible.

- Testing for leaks and performing calibration to guarantee gas flow accuracy.

- Inspecting ventilation and extraction systems to ensure proper fume control in enclosed areas.

Seawater exposure, vibration from engines, and constant changes in temperature can cause rapid deterioration of welding tools and accessories. Without diligent upkeep, even a small issue—like a loose fitting or blocked nozzle—can become catastrophic during active operations.

Compliance UnderRightShip RISQ 2.0 and 3.1

Welding safety isn’t just a technical concern—it’s also a regulatory imperative.

The updated RightShip RISQ 2.0 framework places a stronger focus on hot work safety than ever before. Auditors now assess not only the presence of welding equipment but also its condition, servicing records, and compliance with international standards.

The RISQ 3.1 checklist outlines specific expectations, including:

- Annual inspections of pressure regulators and flashback arrestors, with documented records.

- Component replacement no later than five years from the manufacturing date.

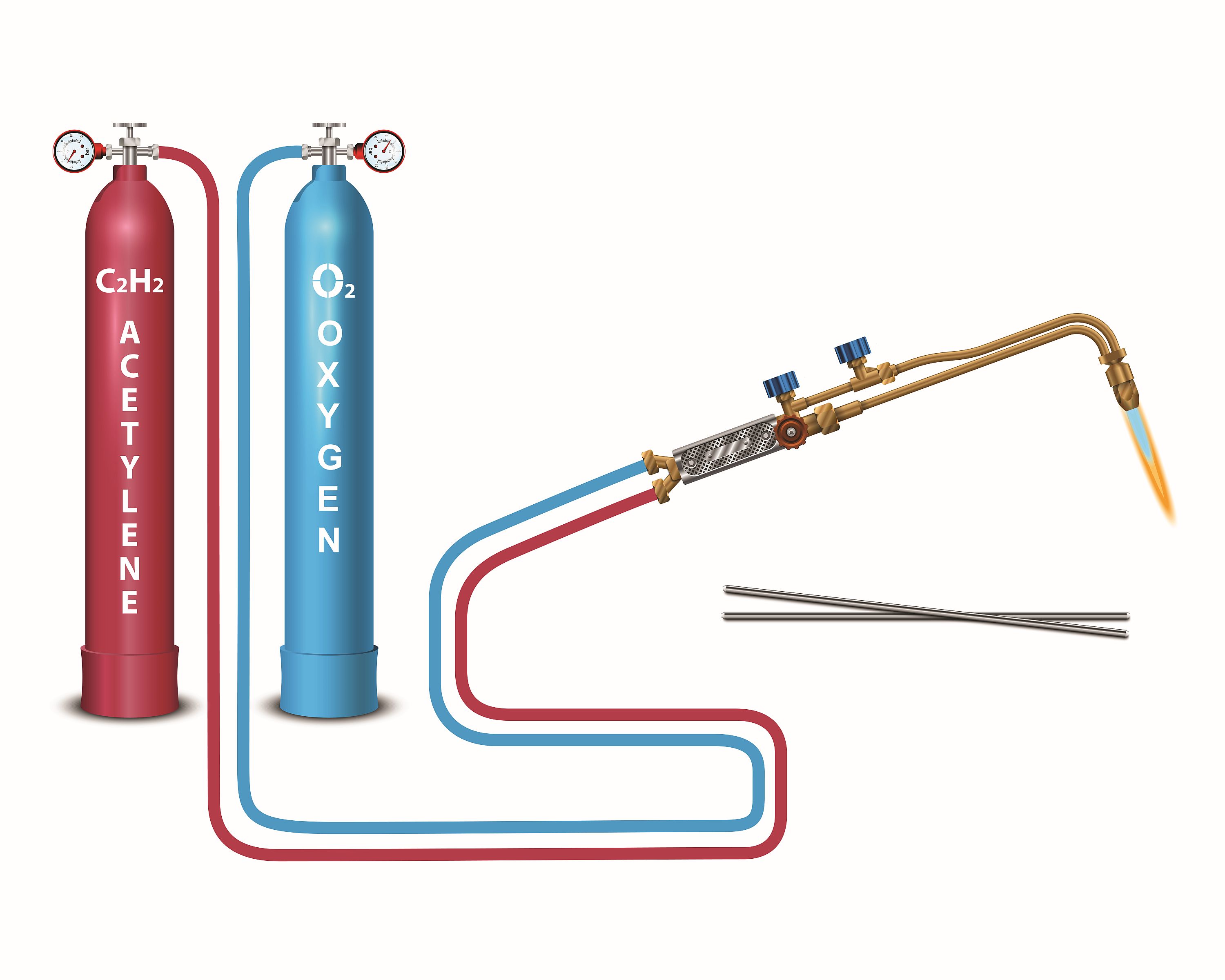

- Color-coded gas lines: blue for oxygen and red for acetylene.

- Mandatory safety fittings, such as non-return valves at torch inlets.

- Pressure testing by qualified personnel, certified per the vessel’s classification society or flag authority.

These are not guidelines—they are obligations. Failure to meet them can lead to failed audits, detention by Port State Control, or even commercial penalties from charterers.

SIRE 2.0: Raising the Bar Further

The transition to OCIMF SIRE 2.0—expected to be fully enforced by the end of 2024—marks another leap forward in inspection rigor. Hot work operations are under increasing scrutiny, and welding practices must now meet even tighter safety thresholds.

To comply, operators must:

- Fit flashback arrestors at both ends (torch and regulator) for extended hose setups.

- Ensure gas hoses meet ISO 3821 / EN 559 standards and pass visual and flex tests.

- Enforce strict shut-off procedures and residual gas venting after each job.

- Keep all PPE—goggles, gloves, jackets—in usable, clean condition.

- Post visible “No Smoking” and hot work safety signage wherever welding occurs.

Neglecting these requirements could see a vessel rejected for charter or subjected to costly delays.

Beyond RightShip and SIRE, oversight comes from:

- Classification societies like DNV and ABS, requiring documented testing for vessel certification.

- Flag states and PSC authorities conducting detailed inspections.

- The ISM Code, which mandates comprehensive risk management—welding included—as part of every vessel’s Safety Management System (SMS).

Each of these bodies holds the authority to penalize non-compliant vessels. The result? Shipowners can’t afford to cut corners on welding safety—not when reputations, certifications, and lives are on the line.

Conclusion: A Strategic Imperative

Welding safety is more than a checkbox; it’s a critical pillar of safe and efficient maritime operations. Properly maintained welding equipment safeguards crews, preserves vessel integrity, and ensures compliance with evolving global standards.

Shipowners and operators must treat this not as an operational detail but as a strategic priority. Investing in servicing, recordkeeping, and crew training is an investment in uninterrupted operations and a stronger safety culture. A safe vessel is a compliant vessel—and a compliant vessel is a commercially viable one. As the maritime industry evolves, let welding safety remain a non-negotiable standard.

“For any additional information or to request service, please feel free to reach out to us at your convenience.”

By Michalis P. Leoutsakos

COO, Poseidon Marine Supplies Group